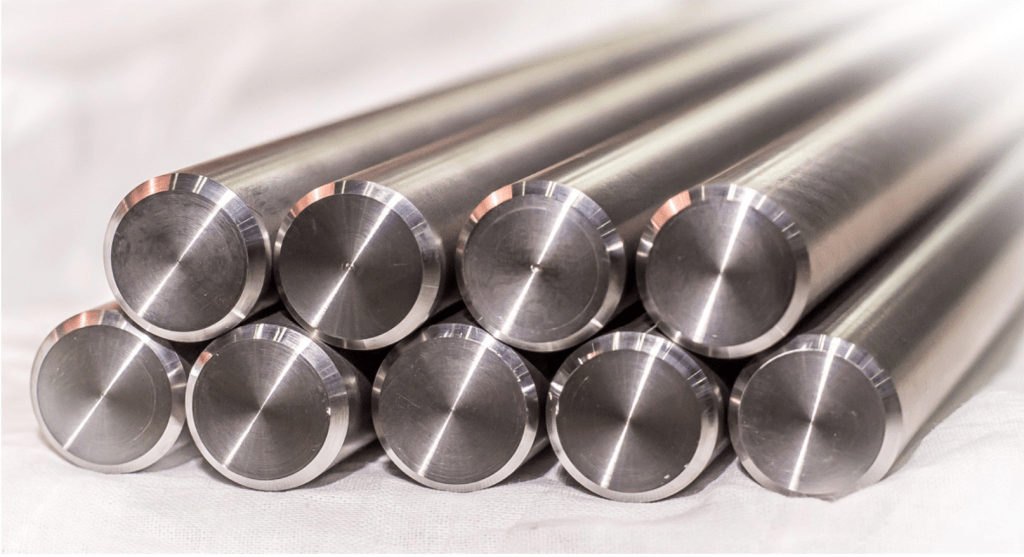

China’s niobium-silicon alloy is another rare metal

This China’s niobium-silicon alloy can withstand extreme temperatures, making it ideal for high-performance aircraft engines, and is ideal for its space experiments for hypersonic flight.

Interesting Engineering • January 7, 2025 ~ SCMP Global Times

Three-year-long experiments conducted at China’s Tiangong space station have yielded groundbreaking results which can boost the performance of hypersonic missiles and vehicles.

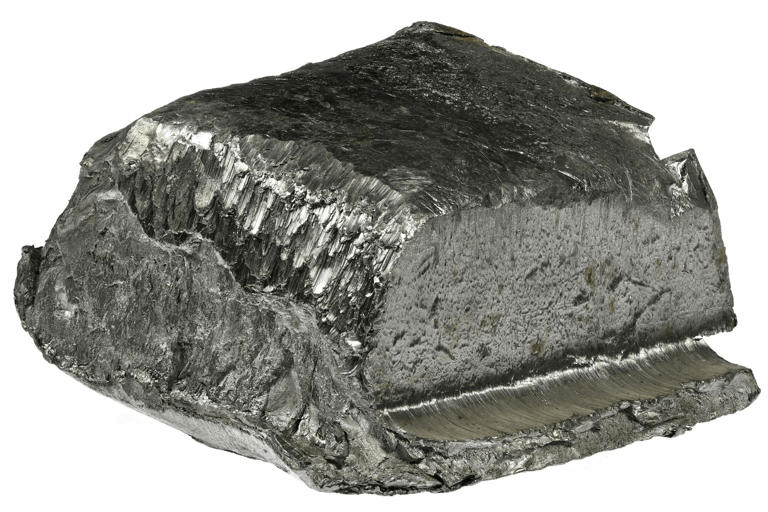

Scientists have used this data to create a new material: niobium-silicon alloy. Niobium is a rare metal primarily used in high-performance steels.

This alloy can withstand extreme temperatures, making it ideal for high-performance aircraft engines.

According to the South China Morning Post (SCMP), turbofan engine blades made from niobium-silicon alloy can endure extremely high temperatures of over 3,092 degrees Fahrenheit (1,700 degrees Celsius).

Better strength and fast process

Niobium-silicon alloy is incredibly difficult to produce. Until now, the niobium-silicon alloy faced two major challenges for mass production: slow crystal growth and brittleness.

Forming the strong crystals often requires a long time – around 100 hours at nearly 2,912 degree Fahrenheit (1,600 degrees Celsius). Moreover, the resulting material is highly brittle at room temperature, which makes it unsuitable for use in engine manufacturing.

The team led by Wei Bingbo, an academician of the Chinese Academy of Sciences and professor with the Northwestern Polytechnical University, has successfully overcome the challenges associated with niobium-silicon alloy production.

They developed a rapid cooling method that enables the production of high-quality niobium-silicon crystals at a speed of nearly 3.5 inch (9 centimeters) per second. This dramatically reduces the production time compared to traditional methods.

The team also incorporated a small amount of hafnium into the alloy to enhance the crystals’ strength. This increased its strength at room temperature by over three times. This improvement addresses the brittleness issue and makes the alloy suitable for use in demanding engine manufacturing processes.

Space station research

This development has implications for China‘s aerospace industry. As per SCMP, the US has imposed sanctions on Chinese universities like Northwestern Polytechnical University, hindering their research.

This university is accelerating the research on advanced tech like hypersonic aircraft.

This has led to increased Chinese government and military support, enabling Wei’s team to conduct experiments on the Chinese space station since 2021.

The microgravity environment of space alters the behavior of materials compared to Earth, where gravity plays a dominant role. In the absence of gravity, processes like crystal growth and solidification occur differently.

The microgravity experiments led to the observation of several unique phenomena.

During the rapid solidification of the niobium-silicon alloy, a distinctive shrinkage pore structure formed in the microgravity environment — unlike what is typically observed on Earth.

The crystal growth patterns observed in space were different from those observed in ground-based experiments. This extensive research and understanding led to the development of niobium-silicon alloy.

As per industry experts, mass production of niobium-silicon alloy could boost China’s military and high-end manufacturing industries.

China’s reliance on imported niobium highlights the strategic importance of this discovery.

Reportedly, the nation is the world’s largest consumer of this rare metal. However, China possesses less than 1 percent of global niobium reserves. Brazil, a major supplier to China and a fellow BRICS member produces nearly 90 percent of the world’s niobium.

The findings were published in the journal Acta Physica Sinica.

China has mastered key technologies for the efficient utilization of niobium resources, enabling the economic development of large-scale niobium-rare earth deposits. The initiative has successfully addressed critical technical challenges, unlocking an estimated 929,000 tons of niobium resources, industry newspaper China Metallurgical News reported on January 13, 2025.