How Xiaomi phones are made

There’s an old joke about the factory of the future. The modern factory will be staffed by a machine, a man, and a dog. The machine will run the factory. The man’s job is to feed the dog, and the dog is trained to bite the man if he tries to touch the machine. China’s already there.

Kevin Walmsley • March 24, 2025

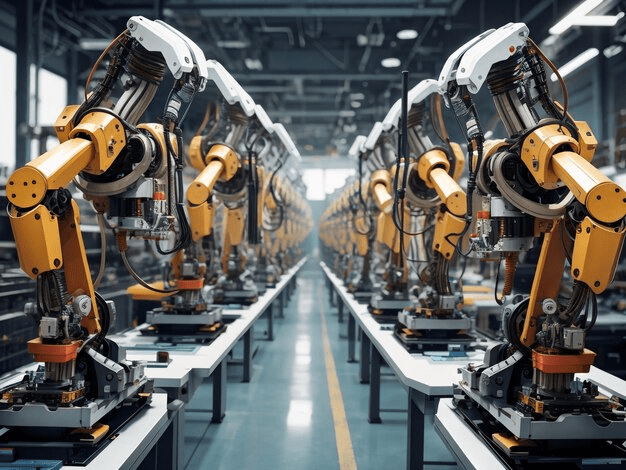

This is news from Xiaomi. Xiaomi is a manufacturer of smartphones. And they’ve opened a smart factory that will produce a smartphone every second. That’s 30 million phones per year with no people. So this is known as a dark factory here. This plant is $330 million. And this is the press announcement from Xiaomi,

which we use this factory to produce their Fold 4 and MixFlip smartphones.

There’s a big dog in that place somewhere. And here’s an announcement that sounds like the script for the Terminator. China’s got a factory of robots building other robots. One robot every 30 minutes, 30,000 robots a year.

And the supply chain is all right there in Shundu in Guangdong province. Over 80% of the products to build those robots come from nearby suppliers. Production costs have been cut by a third. delivery times by 75% from months to weeks. The level of automation in China’s industrial sector needs to be seen to be believed.

I visited a factory two months ago. Our US company, Direct Equipment, is looking hard at having Chinese factories build houses here that will ship over and have our crews erect on site. Low cost quality housing is a serious problem in North America. and our property developers are busy building homes at 300,000, 400,000 and more.

So nobody bothers to build them for any less than that. It’s an opportunity cost problem. New houses are snapped up at 400K. So why should developers bother with home buyers for only $150,000 budgets? So we’re trying to solve part of that problem by having Chinese factories build most of the house here, then ship over.

There’s a factory in Shangchou in Henan Province. And this factory builds high-end recreational vehicles for the Australian market, campers, and what are called capsule houses, another small modular housing units for luxury resorts and hotel properties here in Asia. I called John, my partner in the United States, the night before my visit to this factory.

And I told him it was probably a waste of my time. I was skeptical that a factory of that kind could build houses for the United States because the production process must be different. And we need larger houses anyway, and houses that are built to US residential housing codes. There’s a lot of variation in that.

A home built for a coastal area needs to be highly tolerant to flooding and wind, whereas one built for northern climates needs to support snow loads, for example. But this factory visit was arranged by a friend of mine, and so I agreed to go out of politeness, even though my expectations were really low.

I spent the day there with their teams and took a tour of their plant and went to the hotel and called John again and said, forget everything I told you yesterday. I’m pretty sure now these guys can do whatever we want that if we just give them exactly what we need from your side, they can set their machines up and press a button and six hours later a house comes out of the other end of it.

On the supply chain, everything they need is right there locally within 50 miles of their main plant. And that sounds a lot like the just-in-time manufacturing process and how Toyota built that just-in-time system and blew up Detroit.

But here it’s with a far higher degree of manufacturing efficiency because of the AI systems they use to speed up all the planning and design and in the manufacturing itself. Also, just-in-time requires a highly standardized bill of materials and huge volumes of production with only minor variations product by product, like color, for example.

The just-in-time system cannot work if there is a large degree of customization involved. But these Chinese factories are different. A Toyota plant running a just-in-time system that builds Camrys are making 1,000 Camrys today and 1,000 more tomorrow.

The Camry is the only model that that particular Toyota plant is going to build. But these Chinese factories can do different sizes and layouts no problem, even with very low order quantities. The whole process is amazing, but it’s also a little unsettling to watch. Just a handful of engineers, fewer than 10, take our specifications.

They huddle around their tables for a few days to get the conversions exactly right. Then they turn on their giant machines and build houses for direct equipment today. Tomorrow they’ll build RVs for Australia. And the day after that, they’ll build luxury hotels for Japan.

I tell you, I have a lot of days like that where I’m shocked at what I see. I’ve been here 13 years and I still can’t get over it sometimes. We still don’t know what to make of it. And that’s what this report here is trying to make sense of too. This whole analysis is awesome.

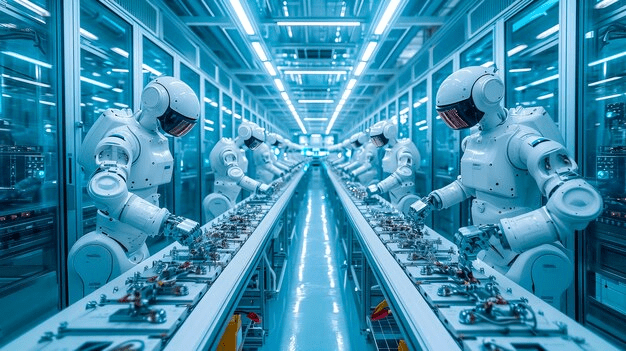

It’s not paywalled and it’s very similar to the reports we put together. They did a really comprehensive job and we’ll be using it as a source for other pieces later. Its focus is China’s robotics industry, and this section here involves Chinese smart factories. It’s not just robots they’re using to help humans carry stuff around or stock shelves.

It’s getting the machines to do literally everything. The level of automation doesn’t exist at all in North America or Europe to this degree. This is not a statement that the United States is losing. It’s to demonstrate an absurd difference in manufacturing proficiency. We’re long past the days of China competing on the basis of low cost labor.

It’s now total domination of the supply chains, of engineering, and an industrial sector that builds machines that build other products entirely on their own. This is taking place now across many industry sectors and product lines. The most extreme example is the dark factories, which is just what they sound like. No lights, no people.

They’re fully automated, powered by AI, and robots and sensors that do literally everything. Assembly, inspection, moving things around, all by robotics. Not having people means energy savings. Light, air conditioning, heat, all the activities that support people. like food preparation and security and parking and everything else, they go away.

The downside of building factories that don’t need people is obvious what to do with the people who you once needed to do all those things before. So it’s going to be a problem there for over 10 million Chinese manufacturing workers now getting them retrained to do something else.

But policy planners in China may see that as a rounding error, given a population of over a billion people, and the new markets that are going to be created by products coming out of their smart factories, like houses in North America, for example. Insiders with a strong understanding of what’s going on in China’s industrial sector estimate that China is probably already the world leader in smart manufacturing, but certainly will be in five years.

Smart manufacturing in China is growing at a compound rate of over 18% per year. The report goes deeply into what this means for the United States and for the other manufacturing centers across the world.

This is a major peeve of mine that we tend to compare China and the United States with absolute dollar figures instead of comparing what a dollar actually buys. China can staff an engineering department faster and much less expensively than a company in California, say, or Germany.

Nevertheless, the growth rates are 18% in China compared to 13.5 in the US. 18% compounded growth for the industry means that it will double here every four years. 13% growth in the US means a doubling every five and a half years. So no matter where things stand right now, it’s just a matter of time.

And here are some of the catalysts on the Chinese side. China’s artificial intelligence models cost just a fraction of what our AI vendors charge. But the elephant in the room is supply chains. Again, cheap AI would be great. It would be great if electricity prices were the same back home as here.

It would be terrific if zoning regulators could get out of the way and let us build things at home again. But smart factories need raw materials to feed into the machines. And China has the raw materials. The United States is striving to reshore manufacturing. We will struggle to replace the supply chain in China.

For more, see

Nature Index: China Surpassed US in Research

Explore ancient China with “25 Puzzling Inventions of Ancient China”